A&N PEAKS

SERVICES

ANPEAKS is Johannesburg's high end all-female detailing studio. Our team of skilled & passionate women are dedicated to bringing out the best in your vehicle with meticulous care & expertise. From intricate Interior Detailing, Paint Protection Film, Ceramic Coatings to flawless exterior finishes, we transform every car into a masterpiece. At ANPEAKS, we believe in the power of precision, the art of detailing & vehicle protection, ensuring your ride looks & feels its absolute best. Experience exceptional service with a personal touch.

Your car deserves nothing less.

Paint Protection Film

Paint Protection Film (PPF) is a clear, durable polyurethane film applied to a vehicle's surface to protect the paint from scratches, chips, and other types of damage. Here’s a detailed overview:

Key Benefits

1. Scratch Resistance: PPF protects against minor scratches and abrasions, maintaining the vehicle's appearance.

2. Stone Chip Protection: It guards against chips from road debris, making it especially useful for the front end of vehicles.

3. UV Protection: PPF often includes UV inhibitors, helping to prevent paint from fading and oxidation.

4. Self-Healing Properties: Many modern films can "heal" minor scratches and swirl marks when exposed to heat.

5. Easy Maintenance: PPF is easy to clean and often comes with a hydrophobic surface that repels dirt and water.

Application Areas

- Hood: To protect against flying debris.

- Fenders and Bumpers: High-impact areas prone to chips.

- Door Edges: Where wear and tear from entering and exiting the vehicle occurs.

- Side Mirrors: Vulnerable to scratches.

- Full Vehicle Wraps: For maximum protection, some opt for full coverage.

Installation Process

1. Surface Preparation: The vehicle is washed and decontaminated.

2. Film Cutting: The film is cut to fit the specific vehicle areas, either by hand or using computer-aided designs.

3. Application: The film is carefully applied to the vehicle, often using a wet application method for ease of adjustment.

4. Trimming: Excess film is trimmed for a seamless look.

5. Curing: The film is left to cure, ensuring strong adhesion.

Maintenance Tips

- Washing: Use our ANPEAKS pH-neutral Snow Foam to avoid damaging the coating. Hand washing is often recommended.

- Avoid Harsh Chemicals: Certain chemicals can damage the film; consult the manufacturer's guidelines.

- Regular Maintenance Washes with your Detailer: To check for any lifting or damage and address it promptly.

Cost Considerations

The price of PPF varies based on factors such as:

- Coverage Area: Full vehicle wraps are more expensive than partial applications.

- Film Quality: Higher-quality films typically cost more but offer better protection.

- Professional Installation: While DIY kits are available, professional installation is recommended for optimal results.

Conclusion

Paint Protection Film is a valuable investment for vehicle owners who want to maintain their car’s appearance and resale value. When properly applied and maintained, it can provide long-lasting protection against everyday wear and tear.

Full Car

All painted panels

Bush Wrap

Full Car up to Window Height. Excluding Pillars & Roof.

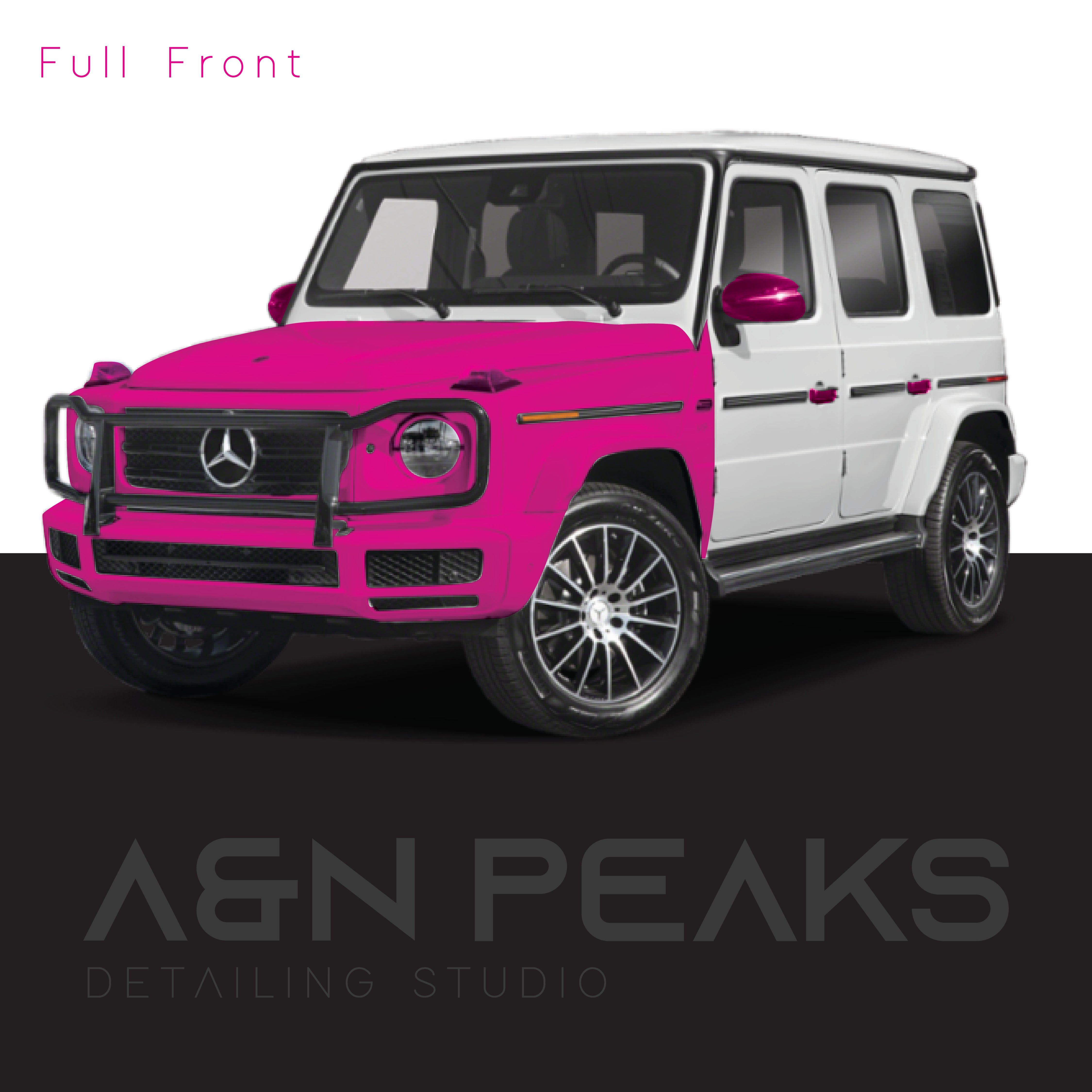

Full Front

Full Front Bumper

Full Bonnet

Full Front Fenders

Headlights

Mirrors

Doorcups

Bootsill

Partial Front

Full Front Bumper

Partial Bonnet

Partial Front Fenders

Headlights

Mirrors

Windscreen

INTERIOR

Painted panels and screen (not cluster)

Paint Protection Film Pre Cut System

A pre-cut Paint Protection Film (PPF) system is designed to simplify the installation process of PPF on vehicles. Here’s a detailed overview of how these systems work, their benefits, and considerations:

What is a Pre-Cut PPF System?

A pre-cut PPF system consists of film pieces that are specifically cut to fit the contours of a vehicle's make and model. These kits are often created using computer-aided design (CAD) software, ensuring precision and a perfect fit for various areas of the vehicle.

Key Benefits

Ease of Installation: Pre-cut kits reduce the complexity of installation since the pieces are already sized and shaped for specific areas, making it easier for both professionals and DIY enthusiasts.

Time-Saving: Because the film is pre-cut, the installation process is quicker than cutting and fitting the film from scratch.

Reduced Waste: Pre-cut systems minimize excess material, which is more economical and environmentally friendly.

Consistency and Accuracy: Computer-generated cuts ensure a high level of accuracy, providing a clean, professional look.

Variety of Options: Kits are available for various vehicles and can cover specific areas like hoods, fenders, bumpers, and more, or can be purchased as full vehicle wraps.

DETAILING

Detailing refers to the thorough cleaning, restoration, and protection of a vehicle, both inside and out. It goes beyond a standard car wash and involves meticulous attention to detail. Here’s an overview of the key aspects of automotive detailing:

Types of Detailing

Exterior Detailing:

Washing: Hand washing the vehicle using two-bucket methods to prevent scratches.

Clay Bar Treatment: Removes embedded contaminants, ensuring a smooth surface.

Polishing: Corrects paint imperfections, swirls, and scratches, enhancing gloss.

Waxing or Sealing: Adds a protective layer to the paint, providing shine and durability.

Wheel and Tyre Care: Cleans and conditions wheels and tires, enhancing their appearance.

Interior Detailing:

Vacuuming: Thoroughly cleans carpets, seats, and mats.

Shampooing: Deep cleans upholstery and carpets, removing stains and odors.

Leather Conditioning: Cleans and conditions leather surfaces to prevent cracking and fading.

Dashboard and Console Care: Cleans and protects all surfaces, including plastic, vinyl, and wood trims.

Engine Bay Cleaning:

Cleaning the engine bay to remove dirt, grease, and grime can enhance appearance and allow for easier maintenance.

Key Benefits

Enhanced Appearance: Detailing significantly improves the overall look of a vehicle, making it more attractive.

Increased Resale Value: A well-maintained vehicle often fetches a higher price when sold.

Protection: Regular detailing helps protect surfaces from wear and tear, UV damage, and contaminants.

Improved Safety: Cleaning headlights and taillights improves visibility, enhancing safety.

Maintenance Tips

Regular Cleaning: Establish a routine to keep the vehicle clean and maintain its appearance.

Protective Measures: Use wax, sealants, ceramic coatings & paint protection film regularly to protect the paint.

Prompt Attention to Stains: Address spills and stains immediately to prevent long-term damage.

Conclusion

Detailing is an essential practice for maintaining a vehicle's appearance and value. Regular detailing contributes to the longevity and overall enjoyment of a vehicle.

Ceramic Coatings

Ceramic coating is a liquid polymer applied to the exterior of a vehicle, forming a chemical bond with the factory paint. This advanced protective layer offers several benefits and enhances the vehicle's appearance. Here’s a detailed overview:

Key Benefits

Durability: Ceramic coatings can last for several years, providing long-lasting protection compared to traditional wax or sealants.

Hydrophobic Properties: The coating repels water and dirt, making it easier to clean and maintain the vehicle's appearance.

UV Protection: It shields the paint from harmful UV rays that can cause oxidation and fading over time.

Chemical Resistance: Ceramic coatings protect against various contaminants, including bird droppings, tree sap, and road contaminants.

Enhanced Gloss: The coating adds a high-gloss finish, enhancing the vehicle’s overall look.

Application Process

Surface Preparation: The vehicle is thoroughly washed and decontaminated, often including clay barring and polishing to ensure a smooth surface.

Application: The ceramic coating is applied in small sections using a specialized applicator, typically in multiple layers for added protection.

Curing: After application, the coating requires a curing period, during which it bonds to the paint. This can range from a few hours to 48 hours depending on the weather.

Maintenance Tips

Regular Washing: Use our ANPEAKS pH-neutral Snow Foam to avoid damaging the coating.

Avoid Automatic Car Washes: These can be too abrasive and may damage the coating.

Use Microfiber Towels: For drying and cleaning, to prevent scratches.

Periodic Inspections: Regularly check for any signs of wear or damage, and consider professional maintenance or reapplication as needed.

Conclusion

Ceramic coatings are an excellent choice for those looking to protect their vehicle's paint and maintain its appearance over the long term. While the initial investment may be higher than traditional waxing, the durability and ease of maintenance often make it worthwhile.

Minor Resprays

Respraying refers to the process of repainting a vehicle's exterior, either partially or entirely. This can be done for various reasons, including repairing damage, changing the color, or refreshing a faded finish. Here’s a detailed overview of the respray process, benefits, and considerations:

Reasons for Respraying

Repair Damage: To fix scratches, dents, or rust that affect the vehicle's appearance and integrity.

Color Change: To update the look of the vehicle or personalize it with a different color.

Fading and Oxidation: To restore a vehicle’s original finish that has deteriorated due to sun exposure or wear.

Improving Value: Enhancing the vehicle's aesthetics can increase its resale value.

Respray Process

Assessment: The vehicle is inspected to determine the areas needing respray and the overall condition of the paint.

Preparation:

Washing: The vehicle is thoroughly cleaned to remove dirt and contaminants.

Sanding: Damaged areas are sanded down to create a smooth surface for the new paint to adhere.

Masking: Areas not being painted (windows, trim, etc.) are masked off to protect them.

Priming: A primer is applied to bare metal or repaired areas to ensure proper adhesion of the topcoat.

Painting:

Base Coat: The chosen color is applied in several thin layers to achieve even coverage.

Clear Coat: A clear protective layer is applied over the base coat to enhance shine and protect against UV rays, chemicals, and scratches.

Curing: The paint is allowed to cure, which can take several hours to a few days, depending on the products used.

Polishing: After curing, the surface may be polished to enhance gloss and remove any imperfections.

Benefits of Respraying

Restoration: Revives the appearance of a vehicle, making it look newer and well-maintained.

Customization: Offers an opportunity for personalization through color changes or special finishes (metallic, matte, etc.).

Protection: New paint provides a fresh layer of protection against environmental factors, such as UV rays and corrosion.

Maintenance After Respray

Curing Time: Avoid washing the vehicle for at least a week after respraying to allow the paint to cure fully.

Protective Coatings: Consider applying a ceramic coating or paint protection film after respraying for added protection.

Regular Care: Regular washing will help maintain the new paint job and keep it looking fresh.

Conclusion

Respraying a vehicle can significantly enhance its appearance and longevity. Whether for repair, customization, or restoration.

Window Film UV Rejection & Safety Film (Smash and Grab)

Window film is a thin, adhesive layer applied to the interior or exterior of vehicle windows, offering a range of benefits including UV rejection, privacy, and safety. Here’s a detailed overview of these aspects:

Types of Window Film

UV Rejection Film:

Purpose: This type of film is designed specifically to block harmful ultraviolet (UV) rays from the sun, which can cause skin damage and contribute to fading in interior materials.

Benefits:

Protects passengers from UV exposure.

Reduces heat buildup inside the vehicle, improving comfort.

Helps preserve the vehicle's interior by preventing fading and cracking.

Smash-and-Grab Film:

Purpose: This film is intended to enhance safety by holding shattered glass together in the event of a break-in or accident.

Benefits:

Deters theft by making it more difficult for criminals to access the interior quickly.

Reduces the risk of injury from shattered glass.

Provides additional structural integrity to the windows.

Key Benefits of Window Film

Heat Reduction: Both UV rejection and reflective films can significantly reduce heat inside the vehicle, making air conditioning more effective and improving overall comfort.

Glare Reduction: Window films can minimize glare from sunlight, enhancing visibility for drivers and passengers.

Privacy and Security: Tinted films can offer increased privacy for passengers and belongings, as well as deter potential theft.

Aesthetic Appeal: Various shades and finishes can enhance the vehicle's look, giving it a more customized appearance.

Installation Process

Surface Preparation: Windows are cleaned thoroughly to remove dirt and contaminants.

Measuring and Cutting: The film is measured and cut to fit each window precisely.

Application: The film is applied using a wet method to allow for adjustments and to eliminate air bubbles.

Curing: The film needs time to cure and adhere properly, which can vary based on humidity and temperature.

Considerations

Legal Regulations: Many countries have laws regarding the level of tinting allowed on vehicle windows, particularly for front windshields and side windows. It’s essential to check your local laws to ensure compliance.

Quality of Film: There are various types and qualities of window films available. Higher-quality films typically offer better UV rejection, durability, and aesthetics.

Maintenance Tips

Cleaning: Use gentle, non-abrasive cleaners to maintain the film’s appearance. Avoid ammonia-based products, which can damage the film. A perfect example of what to use is our ANPEAKS Window Cleaner

Avoid Roll-Down: Do not roll down windows for a few days after installation to allow the film to adhere properly.

Regular Inspections: Check for any peeling or bubbling, especially around the edges, and address any issues promptly.

Conclusion

Window film provides multiple benefits, including UV protection, safety against smash-and-grab incidents, and enhanced aesthetics. By understanding the various types of window film and their advantages, vehicle owners can make informed decisions to improve their driving experience and protect their investment.

STONE CHIP REPAIR

Stone chip repair involves the process of fixing small chips, and scratches on a vehicle's paint surface caused by road debris, such as stones and gravel. Here’s an in-depth look at the stone chip repair process, its benefits, and key considerations:

Causes of Stone Chips

Road Debris: Loose stones, gravel, and other materials on the road can hit the vehicle at high speeds, causing paint damage.

Environmental Factors: Weather conditions, like hail or strong winds, can also contribute to paint chipping.

Repair Process

Assessment:

Inspect the damaged areas to determine the extent of the chips and whether any underlying issues (like rust) need addressing.

Cleaning:

Thoroughly clean the affected area using a gentle car wash soap and water to remove dirt, grime, and contaminants.

Ensure the area is completely dry before proceeding.

Sanding (if necessary):

For larger chips or scratches, lightly sand the area to smooth out the edges and prepare it for repair. Use fine-grit sandpaper to avoid further damage.

Filling:

Use a touch-up paint that matches the vehicle’s color. Many manufacturers provide color codes to ensure a perfect match.

Apply the paint carefully into the chip using a fine brush or a toothpick, filling it just above the surface level.

Blending:

After the paint dries, use a polishing compound to blend the repaired area with the surrounding paint. This step helps minimize the visibility of the repair.

Sealing:

For added protection, consider applying a clear coat over the repaired area to protect it from future damage and enhance shine.

Maintenance After Repair

Regular Cleaning: Keep the vehicle clean to prevent further damage and make repairs easier to spot.

Inspection: Periodically check for new chips or damage, especially after long drives or inclement weather.

Conclusion

Stone chip repair is an essential aspect of vehicle maintenance that can save money, preserve value, and enhance appearance. Addressing stone chips promptly is key to maintaining a vehicle's aesthetic and structural integrity.

Mag / Wheel Repair

Mag or wheel repair involves fixing damage to a vehicle's wheels, particularly those made from alloy (often referred to as "mag" wheels). Damage can occur due to various factors, such as potholes, curb impacts, or general wear and tear. Here’s a comprehensive overview of the mag/wheel repair process, its benefits, and key considerations:

Types of Damage

Scratches and Scuffs: Cosmetic damage that affects the finish of the wheel.

Bent Rims: Often caused by hitting a pothole or curb, leading to air leaks and tire issues.

Cracks: Structural damage that can compromise the wheel's integrity.

Corrosion: Caused by exposure to the elements, particularly road salt and moisture.

Repair Process:

Assessment:

Inspect the wheel to determine the type and extent of the damage. Check for cracks, bends, and structural integrity.

Cleaning:

Thoroughly clean the wheel to remove dirt, brake dust, and contaminants. This step is crucial for ensuring proper adhesion during the repair.

Repairing Scratches and Scuffs:

For minor scratches, a sanding process may be used to smooth the surface, followed by the application of touch-up paint or a clear coat.

For deeper scuffs, a specialized wheel repair kit can be utilized, which may include filler and paint.

Straightening Bent Rims:

Bent rims can often be straightened using specialized equipment. This involves applying pressure to the bent area to return it to its original shape.

In some cases, the wheel may need to be replaced if the damage is too severe.

Repairing Cracks:

Cracked wheels may require welding or a specialized epoxy to fill the crack. This process should be done by professionals to ensure safety and structural integrity.

Finishing:

After repairs, the wheel may need to be polished or re-coated to restore its original appearance. Clear coat may also be applied to protect the finish.

Benefits of Wheel Repair

Cost-Effective: Repairing a wheel is generally much cheaper than replacing it entirely.

Aesthetic Improvement: Fixing cosmetic damage enhances the overall look of the vehicle.

Safety: Addressing structural issues helps prevent tire blowouts and improves vehicle safety.

Increased Resale Value: A well-maintained set of wheels contributes to the overall value of the vehicle.

Considerations

Professional vs. DIY: While some minor repairs can be done at home with kits, professional services often yield better results, especially for structural damage.

Time and Costs: The time and cost of repairs can vary based on the extent of the damage. Simple cosmetic repairs are quicker and cheaper than fixing bent or cracked rims.

Warranty and Liability: Check if the wheels are still under warranty; some manufacturers may cover certain types of damage.

Maintenance Tips

Regular Inspections: Periodically check wheels for signs of damage, such as cracks, bends, or corrosion.

Careful Driving: Avoid hitting curbs and potholes to minimize the risk of damage.

Cleaning: Regularly clean wheels to prevent brake dust buildup, which can lead to corrosion.

Conclusion

Mag or wheel repair is an important aspect of vehicle maintenance that can enhance safety, aesthetics, and overall vehicle value. Whether addressing minor scratches or significant structural damage, timely repairs can help keep your wheels in optimal condition.

Upholstery

Upholstery refers to the materials and fabrics used to cover and furnish the interior of a vehicle, including seats, door panels, headliners, and other surfaces. Proper care and maintenance of automotive upholstery are essential for enhancing comfort, aesthetic appeal, and overall vehicle value. Here’s a detailed overview:

Types of Upholstery Materials

Fabric:

Commonly used for seats and door panels.

Variety of textures and patterns.

Generally more affordable but may require more maintenance to prevent stains and wear.

Leather:

Offers a premium look and feel.

Durable and easy to clean but can be prone to cracking and fading if not properly maintained.

Requires conditioning to keep it supple and prevent dryness.

Suede and Alcantara:

Used in higher-end vehicles for a luxurious touch.

Requires careful cleaning and maintenance, as they can stain easily.

Benefits of Quality Upholstery

Comfort: High-quality upholstery enhances the comfort of the vehicle's interior, making longer drives more enjoyable.

Aesthetics: Good upholstery improves the overall look of the vehicle, adding to its appeal and potentially increasing resale value.

Durability: Quality materials are designed to withstand wear and tear, ensuring the interior looks good for longer.

Care and Maintenance

Regular Cleaning:

Vacuum upholstery regularly to remove dirt and debris.

For fabric, use a fabric cleaner to address stains and spills; for leather, use a designated leather cleaner.

Conditioning:

For leather upholstery, use a leather conditioner periodically to maintain suppleness and prevent cracking.

Stain Removal:

Address spills immediately to prevent stains. Blot (don’t rub) the area with a clean cloth and use appropriate cleaners for specific materials.

Protective Treatments:

Consider applying protective sprays for fabric to repel stains and spills.

For leather, protective creams can help create a barrier against moisture and dirt.

Common Issues and Repairs

Tears and Rips: Can often be repaired with patch kits or by a professional upholsterer.

Fading: Exposure to sunlight can cause upholstery to fade. Use sunshades and park in shaded areas to minimize this.

Cracking: Especially common in leather, regular conditioning can help reduce the risk of cracking.

Odors: Use fabric refreshers or specialized odor removers for upholstery; consider professional cleaning if odors persist.

Professional Upholstery Services

For significant repairs or upgrades, professional upholstery services can:

Reupholster seats and panels with new materials.

Repair or replace damaged areas.

Customize interiors to enhance aesthetic appeal.

Conclusion

Upholstery is a vital component of a vehicle’s interior, impacting both comfort and aesthetics. Proper care and maintenance can significantly extend the life of upholstery materials, enhancing the driving experience and maintaining vehicle value. Whether through regular cleaning, conditioning, or professional services, attention to upholstery ensures a pleasant and inviting vehicle interior.

Paintless Dent Removal

Paintless Dent Removal (PDR) is a specialized technique used to repair minor dents and dings in a vehicle's body without the need for repainting. This method is particularly effective for preserving the original factory finish of the paint. Here’s an in-depth overview of PDR, how it works, its benefits, and considerations:

How Paintless Dent Removal Works

Assessment: A technician inspects the vehicle to determine the extent and location of the damage. PDR is most effective for shallow dents without creases.

Accessing the Dent: The technician often gains access to the back of the panel where the dent is located. This may involve removing interior panels, tail lights, or other components.

Finishing Touches: Once the dent is removed, the technician inspects the area for any imperfections and may perform additional smoothing as needed.

Benefits of Paintless Dent Removal

Cost-Effective: PDR is typically less expensive than traditional bodywork, which involves repainting and extensive labor.

Time-Saving: Repairs can often be completed within hours, whereas traditional repairs may take days.

Preserves Original Paint: Since the factory paint is not disturbed, PDR maintains the vehicle’s value and appearance.

Environmentally Friendly: PDR doesn’t require paints, fillers, or solvents, making it a more eco-friendly option.

Limitations of Paint Less Dent Removal

Not Suitable for All Dents: PDR is most effective for shallow dents without creases or damage to the paint. Deep dents, large dents, or those with severe creasing may not be suitable for PDR.

Requires Skill: Successful PDR requires a trained and experienced technician to ensure optimal results. Poor technique can lead to further damage.

Limited Access: In some cases, access to the back of the panel may be difficult, limiting the effectiveness of the technique.

When to Consider Paintless Dent Removal

Minor Dents and Dings: Ideal for hail damage, door dings, and small dents caused by shopping carts or minor impacts.

Preserving Resale Value: If you want to maintain the original finish and value of your vehicle, PDR is a good option.

Quick Repairs Needed: When you need a fast turnaround without sacrificing quality.

Maintenance After PDR

Regular Washing: Maintain the vehicle’s appearance with regular washes.

Avoid Parking in High-Risk Areas: To prevent future dents, try to avoid parking near heavy traffic or crowded areas.

Conclusion

Paintless Dent Removal is a highly effective method for repairing minor dents and dings while preserving the vehicle's original paint. Its cost-effectiveness, speed, and environmental benefits make it an attractive option for many vehicle owners. By understanding its capabilities and limitations, you can make informed decisions about maintaining your vehicle's appearance.

Car Accessories & Removal

Improving your vehicle's appearance through accessories can enhance its aesthetic appeal, reflect your personal style, and even increase its resale value. Here’s a detailed overview of various accessories that can help make your car look better:

Exterior Accessories

Front Splitters:

Function: Enhance aerodynamics and add a sporty look.

Aesthetic Benefit: Creates a more aggressive stance and lowers the car’s profile.

Spoilers:

Function: Reduces lift and improves stability at high speeds.

Aesthetic Benefit: Adds a dynamic, performance-oriented appearance to the rear of the car.

Side Skirts:

Function: Improve aerodynamics and reduce airflow underneath the car.

Aesthetic Benefit: Visually lowers the vehicle and gives it a more cohesive look.

Custom Grilles:

Function: Improve airflow to the engine.

Aesthetic Benefit: Unique designs can drastically change the front-end look of the vehicle.

Fender Flares:

Function: Increase tire clearance for wider wheels.

Aesthetic Benefit: Gives a more rugged and aggressive look, particularly for off-road vehicles.

Conclusion

Investing in vehicle accessories can significantly enhance your car’s appearance, making it stand out on the road. Whether you’re looking for performance-oriented upgrades or simply want to personalize your ride, there are plenty of options available. Always consider the quality, compatibility, and installation requirements of any accessories you choose to ensure a seamless enhancement to your vehicle’s aesthetics.

Vinyl

Vinyl is a versatile and widely used material in various applications, including vehicle wraps, graphics, decals, and protective coatings. Here’s a detailed overview of vinyl, its types, applications, benefits, and considerations:

Overview of Vinyl

Composition: Vinyl is a synthetic plastic polymer known as polyvinyl chloride (PVC). It can be manufactured in various forms, including rigid and flexible sheets.

Variety of Finishes: Vinyl comes in various finishes, including matte, glossy, satin, and textured, allowing for diverse aesthetic options.

Characteristics: Made from vinyl that is heated and rolled into sheets; generally thicker and less expensive than cast vinyl.

Applications: Suitable for flat surfaces and short-term applications, such as temporary signage.

Vinyl Wraps:

Characteristics: Large sheets of vinyl used to cover the exterior of vehicles, allowing for color changes or custom graphics without repainting.

Applications: Used for branding, personalizing vehicles, or protecting the original paint.

Vinyl Decals and Graphics:

Characteristics: Cut from vinyl sheets and can be applied to various surfaces.

Applications: Used for logos, designs, and decorative elements on vehicles, walls, and windows.

Vinyl Film:

Characteristics: Thin sheets of vinyl used for protection and aesthetics.

Applications: Used for paint protection films, window tints, and decorative finishes.

Benefits of Vinyl

Durability: High-quality vinyl can withstand harsh weather conditions, UV exposure, and wear and tear, making it suitable for outdoor applications.

Cost-Effective: Compared to repainting a vehicle or surface, vinyl wraps and decals can provide a more affordable alternative for customization and protection.

Customizability: Vinyl can be printed, cut, and designed in countless colors and patterns, allowing for personalized designs.

Protective Qualities: Vinyl wraps and films can protect surfaces from scratches, chips, and fading, preserving the original finish underneath.

Applications of Vinyl

Vehicle Wrapping: Changing the color of a car or adding custom graphics without permanent paint.

Considerations

Quality: Choose high-quality vinyl to ensure durability and longevity. Lower-quality vinyl may fade, peel, or crack more quickly.

Application Surface: Ensure the surface is clean, smooth, and suitable for vinyl application to achieve the best results.

Weather Resistance: While many vinyl products are designed for outdoor use, extreme conditions can impact their longevity. Regular maintenance can help extend their life.

Removal: When removing vinyl wraps or decals, it’s essential to contact a professional.

Local Regulations: Check for any local laws regarding vehicle wraps or signage, especially for commercial vehicles.

Conclusion

Vinyl is a highly adaptable material with numerous applications across various industries. Whether for personalizing a vehicle, creating signage, or, vinyl offers durability, customization, and aesthetic appeal. Understanding the types and benefits of vinyl can help you make informed decisions for your projects, ensuring successful results.

Vinyl & PPF Removal

If you're considering having vinyl wraps or paint protection film (PPF) removed by a professional, here’s what you need to know about the process and the benefits of opting for expert services:

Benefits of Professional Removal

Expertise and Experience: Professionals have extensive experience and training in removing vinyl and PPF, ensuring a clean removal without damaging the vehicle's paint.

Specialized Tools: They use specialized equipment, such as heat guns, scrapers, and adhesive removers, which may not be readily available to DIY enthusiasts.

Time Efficiency: Professionals can complete the removal process more quickly, saving you time and effort.

Quality Assurance: A professional service often comes with a guarantee, ensuring that the job is done correctly and to a high standard.

Surface Inspection: After removal, professionals can inspect the vehicle's surface for any potential issues, such as paint damage or residue, and recommend appropriate solutions.

The Professional Removal Process

Initial Assessment:

The technician will examine the vinyl or PPF to determine its condition and the best removal approach.

Preparation:

The vehicle is cleaned to remove dirt and debris, ensuring a safe working environment.

Heating:

Professionals apply controlled heat to soften the adhesive, making the vinyl or PPF easier to peel off.

Peeling and Removing:

Using precision tools, the technician carefully lifts and peels the material away from the surface, minimising the risk of damage.

Adhesive Removal:

Any leftover adhesive is treated with specialised solvents or removers to ensure a clean surface.

Final Cleaning:

The area is thoroughly cleaned and inspected to ensure no residue remains and the surface is pristine.

Conclusion

Opting for professional removal of vinyl wraps and paint protection film ensures a seamless process that protects your vehicle’s surface while providing high-quality results. With their expertise, specialized tools, and commitment to quality, professionals can help you achieve a clean removal while addressing any underlying concerns. If you're considering this option, researching local professionals and consulting with them can set you on the right path.

MAGNETIC NUMBER PLATES

Magnetic number plates are a convenient and versatile option for displaying vehicle registration numbers. They are typically done with strong magnets and can be easily applied and removed from a vehicle's body. Here’s a detailed overview of magnetic number plates, their benefits, types, and considerations:

Overview of Magnetic Number Plates

Material: Magnetic number plates are usually done with strong magnets that we adhere to number plate, making them easy to attach and detach.

Benefits of Magnetic Number Plates

Flexibility:

Great for vehicles used for multiple purposes (e.g., Everyday car or weekend car that is also a showcar).

Protects Original Paint:

Unlike traditional adhesive or sticker plates, magnetic plates do not permanently adhere to the vehicle, reducing the risk of damage to the paint.

Legal Compliance:

In many countries, magnetic number plates can meet legal requirements for displaying registration numbers, though it’s essential to check local laws.

Considerations When Using Magnetic Number Plates

Legal Regulations:

Check local laws and regulations to ensure magnetic number plates are acceptable in your area. Some countries may have specific requirements for the display of registration numbers.

Visibility:

Ensure that the number plate is clearly visible and complies with visibility regulations. Clean the plate and the vehicle surface regularly to prevent dirt buildup.

Installation:

Should be installed by professionals as the bumpers will need to be removed to safely attach the magnets to the inside of the bumpers and the other set of magnets to the number plates.

Conclusion

Magnetic number plates are a practical and flexible solution for vehicle shows & display cars.

Detailing & Aftercare Products

Detailing and aftercare products are essential for maintaining a vehicle’s appearance and protecting its surfaces. Here's a comprehensive overview of detailing, the types of products used, their benefits, and tips for effective aftercare.

Overview of Detailing

Detailing involves a thorough cleaning and restoration of a vehicle, both inside and out. Unlike a standard car wash, detailing focuses on meticulous cleaning, polishing, and protection, enhancing the vehicle's appearance and longevity.

Types of Detailing Products

Exterior Detailing Products:

Car Wash Soap: pH-balanced soaps, such as our ANPEAKS Snow Foam and Pre Wash, designed to safely clean the car's exterior without stripping protective coatings.

Clay Bars: Used to remove embedded contaminants from the paint, leaving a smooth surface, we also offer a Clay Bar.

Polishes: Formulations that help remove light scratches, swirls, and oxidation to restore shine.

Wax and Sealants: Provide a protective layer over the paint. Wax gives a warm glow, while sealants offer longer-lasting protection.

Ceramic Coatings: Advanced products that bond to the paint, offering superior protection against environmental contaminants and UV rays.

Wheel Cleaners: Specialized cleaners, such as our ANPEAKS Wheel Cleaner, is designed to remove brake dust and grime from wheels without damaging the finish.

Glass Cleaners: Streak-free cleaners for windows and mirrors, such as our ANPEAKS Window Cleaner, often formulated to repel water.

Interior Detailing Products:

Upholstery Cleaners: Designed for fabric seats and carpets, such as our ANPEAKS Interior Cleaner, these products effectively remove stains and odors.

Leather Cleaners and Conditioners: Products specifically formulated for leather surfaces to clean and nourish, preventing cracks and fading.

All-Purpose Cleaners: Versatile cleaners for dashboards, plastics, and other interior surfaces.

Odor Eliminators: Sprays or treatments designed to neutralize odors inside the vehicle.

Aftercare Products:

Detailing Sprays: Quick detailers that can be used between washes to maintain shine and remove light dust, such as our ANPEAKS Speedy Detailer.

Tyre Dressings: Products that enhance the appearance of tires, providing a rich, dark finish and protection against UV damage, such as our ANPEAKS Tyre & Trim Protect.

Microfiber Towels: Soft, non-abrasive towels for drying, polishing, and applying products without scratching surfaces.

Applicator Pads: Used for applying wax, sealants, or polishes evenly, such as our Wax Applicator.

Benefits of Detailing and Aftercare Products

Enhanced Appearance: Regular detailing improves the vehicle’s look, restoring paint gloss and interior cleanliness.

Protection: Many detailing products provide protection against UV rays, road grime, and environmental contaminants, prolonging the life of your vehicle's surfaces.

Increased Resale Value: A well-maintained vehicle can command a higher resale price.

Improved Comfort: Clean interiors and fresh scents enhance the driving experience.

Preventative Maintenance: Regular use of detailing products can prevent damage, such as paint oxidation and interior wear.

Tips for Effective Detailing and Aftercare

Frequency: Detail your vehicle regularly—exterior washes every couple of weeks, and thorough detailing every few months, depending on usage and exposure.

Use Quality Products: Invest in high-quality detailing products tailored to your vehicle’s needs for better results.

Follow Instructions: Always read and follow product instructions for application and safety precautions.

Work in Sections: When detailing, work on one section at a time to ensure thorough cleaning and application.

Protect Surfaces: After washing and detailing, apply a protective wax or sealant to maintain shine and protection.

Store Products Properly: Keep detailing products in a cool, dry place to ensure their effectiveness.

Conclusion

Detailing and aftercare products play a crucial role in maintaining your vehicle’s aesthetics and protecting its surfaces. By using the right products and following a regular maintenance schedule, you can keep your vehicle looking great and extend its lifespan. Whether you’re a DIY enthusiast or prefer professional detailing services, understanding these products will help you make informed decisions for your vehicle's care.

CARBON FIBRE REPAIRS

Carbon fiber repair involves techniques to fix damage to carbon fiber composites, commonly used in high-performance applications like automotive parts, aerospace, and sporting goods. Here’s a detailed overview of carbon fiber repair processes, techniques, and considerations.

Overview of Carbon Fiber

Composition: Carbon fiber is a lightweight, high-strength material made from thin strands of carbon atoms woven together. It is known for its exceptional strength-to-weight ratio and rigidity.

Applications: Commonly used in:

Automotive components (e.g., body panels, hoods)

Aerospace structures

Sports equipment (e.g., bicycles, golf clubs)

Industrial applications

Types of Damage

Surface Scratches: Minor abrasions that can affect the appearance but may not compromise structural integrity.

Cracks: Can range from superficial to deep, affecting the material’s strength.

Delamination: Occurs when layers of carbon fiber separate, weakening the structure.

Breakage: Complete fractures requiring more extensive repair.

Repair Techniques

Surface Repair:

Cleaning: Remove any dirt, grease, or contaminants from the damaged area.

Sanding: Lightly sand the damaged surface to prepare for repair.

Epoxy Application: For minor scratches, a resin or epoxy can be applied to fill in the surface and restore appearance.

Crack Repair:

Preparation: Clean and sand the area around the crack.

Resin Infusion: Use epoxy resin to fill the crack. For larger cracks, additional carbon fiber layers may be applied.

Curing: Allow the resin to cure as per the manufacturer’s specifications.

Delamination Repair:

Accessing Layers: Carefully separate the delaminated layers.

Resin Injection: Inject epoxy resin into the gap between layers and press them back together.

Curing: Use clamps or weights to hold the layers in place during curing.

Complete Breakage Repair:

Reinforcement: Cut new carbon fiber pieces to fit over the break.

Layering: Use epoxy resin to bond the new pieces to the original structure.

Sanding and Finishing: Once cured, sand the area smooth and apply a finish coat if necessary.

Considerations for Repair

Expertise Required: Carbon fiber repair can be complex and may require specialized knowledge and skills. If the damage is extensive, consulting a professional is advisable.

Material Quality: Always use high-quality carbon fiber materials and epoxy resins designed for composite repairs to ensure durability and strength.

Weight Considerations: Maintaining the original weight and balance of the component is crucial, especially in high-performance applications.

Inspection: After repair, the component should be inspected for structural integrity, especially if it will be subjected to stress.

Cost: Repairing carbon fiber can be more expensive than repairing traditional materials, but it is often more economical than replacement.

Conclusion

Repairing carbon fiber components is a specialized process that requires careful attention to detail and the right materials. Understanding the types of damage and appropriate repair techniques can help extend the life of carbon fiber products, maintaining their performance and aesthetics. Whether you choose to tackle the repair yourself or seek professional assistance, ensuring a high-quality repair is essential for safety and durability.

BRAND INFORMATION

Stek

- DYNOshield:

DYNOshield provides you with unparalleled top-coated paint protection film technology for those seeking the best-performing film on the market.

Our Nano-glass topcoat is bonded to the film at a molecular level during manufacturing virtually eliminating the need for waxes or after-market top coatings. DYNOshield is unique in the market because of STEK's combination of an extremely hydrophobic top coating plus self-healing properties for correction of light surface scratches.

Our topcoat combined with UV-resistant anti-yellowing adhesives results in unmatched clarity and gloss plus improved puncture resistance. DYNOshield – the best automotive paint protection available from one of the worlds’ leading paint protection film manufacturers.

DYNOshield Specifications

Glossy Finish

Hydrophobic (Advanced water repelling properties)

Anti-Contamination (Easy to remove contaminants)

Fast Recovery

Stain Resistant

10 Year Warranty

DYNOshield paint protection film is warrantied for 10 Years against de-lamination, yellowing, bubbling and cracking.

- DYNOlite:

DYNOlite (PROshield) is our premium 8mm paint protection film, that gives you a clear urethane film with a built in anti-contaminant coating and the ability to self heal light surface scratches.

This means DYNOlite is stain resistant and very easy to clean, with a clear and glossy finish.

Specifications

Glossy Finish

Anti-Contamination (Easy to remove contaminants)

Fast Recovery (by heat or hot water)

Stain Resistant

UV-resistant and anti-yellowing

5 Year Warranty

DYNOlite (PROshield) paint protection film is warrantied for 5 Years against de-lamination, yellowing, bubbling and cracking.

- DYNOmatt:

DYNOmatt is everything you want and need from DYNOshield but with the aesthetics of a smooth matte finish. You don't have to pay a premium for a paint to option or a sub-par paint job. Feel confident your vehicle is protected, preserving your original paint and giving you the matte finish, you've always wanted on whatever colour you already have.

Our topcoat combined with UV-resistant anti-yellowing adhesives results in unmatched clarity plus improved puncture resistance. DYNOmatt – the best automotive paint protection available from one of the worlds’ leading paint protection film manufacturers.

Specifications

Matte Finish

Hydrophobic (Advanced water repelling properties)

Anti-Contamination (Easy to remove contaminants)

Fast Recovery

Stain Resistant

7 Year Warranty

DYNOmatt paint protection film is warrantied for 7 Years against

de-lamination, yellowing, bubbling and cracking.

- DYNOcarbon:

DYNOcarbon the latest innovation from STEK - Paint Protection Film with a carbon fibre pattern.

Perfect for accenting your vehicle and providing you with protection. DYNOcarbon comes with the features you've come to expect from STEK films: hydrophobic, self-healing, puncture resistant and stain resistant. Unlike carbon fibre vinyl, DYNOcarbon is 8mils thick providing you with actual protection.

Specifications

Carbon Fiber Pattern

Hydrophobic (Advanced water repelling properties)

Anti-Contamination (Easy to remove contaminants)

Fast Recovery

Stain Resistant

7 Year Warranty

DYNOcarbon paint protection film is warrantied for 7 Years against delamination, yellowing, bubbling and cracking.

Plus many more.

BRAND INFORMATION

Lamin8 ClearGuard

Helps keep your vehicle in that showroom condition by providing a virtually invisible barrier minimizing stone chips, protecting from minor abrasions, bug stains, and ultimately protecting your investment whilst helping to maintain the resale value of your vehicle.

Protect Your Paint, Protect Your Investment.

Combining excellent elastic properties and optical clarity with high a high shear & tack adhesive, ClearGuard Ultra Self Healing is Warranted against degradation from UV, staining and cracking. ClearGuard Ultra Self Healing applies easily and maintains its clarity, durability and superior performance over a wide range of environmental conditions; providing improved chemical and mechanical resistance (like stone chip) whilst offering conformability to complex shapes and curves. Find out more about ClearGuard Ultra Self Healing and its lifetime warranty at www.ClearGuardSA.co.za.

BRAND INFORMATION

Gtechniq

- Crystal Serum

Why Crystal Serum Ultra?

Crystal Serum Ultra is the best paint protection you can get, it keeps your car looking glossy and new, prolonging the life of your paintworks perfect finish.

Key to Crystal Serum Ultras performance gain is the introduction of a revolutionary new 7nm nanoparticle alongside an existing 20nm nanoparticle and increasing the ratio of crosslinkers which reinforce and thicken the top layer of the coating.

The hard 10h top and softer 7h base layer offer improved swirl resistance over regular 9h paint protection coatings. Compared to standard ceramic paint coatings, Crystal Serum Ultra can withstand even the strongest wash chemicals and bird droppings.

An additional benefit from having a flexible base layer and the hard top layer is that Crystal Serum Ultra is very resistant to extreme heat changes, even from -40 degrees Celsius to +250 degrees Celsius.

Crystal Serum Ultra can be applied either as a stand-alone paint protection product or for the best hydrophobic performance, it can be over coated with Gtechniq EXO or C2.

- Halo Flexible Film Coating:

Why Use Gtechniq HALOv2 Flexible Film Coating?

By utilising the latest in weatherproof composite siloxane technology HALOv2 enhances the performance of Paint Protection Film (PPF) and vinyl. It’s a chemically bonding, ultra-dense flexible film that becomes the permanent surface of the film – protecting it from the elements a car faces on a daily basis. The density of the coating and its low surface energy improve dirt and water repellency of PPF or vinyl. It also helps to prevent staining from dirt ingress and reduce yellowing caused by UV rays.

A key component of the HALOv2 is that it now only requires one layer of product to be applied, rather than the previous version which required two layers, saving time, effort and making maintenance a breeze.

Overall, HALO keeps the PPF looking in a much better condition and makes it much easier for people to keep their car clean following PPF/ vinyl application.

Rigorous real-world and laboratory testing has proven HALO to be compatible with all types of gloss, matte, and satin vinyl and PPF. It is also proven to work on the latest self-healing and pre-treated hydrophobic films.

- Crystal Serum Light:

Why Use Gtechniq Crystal Serum Light?

Crystal Serum Light is the prosumer version of the world-famous Gtechniq Accredited Detailer Crystal Serum Ultra. It offers 80% of professional Serum Ultra’s performance, but if applied incorrectly can be machine polished from your vehicles paintwork.

When it comes to adding gloss, resisting swirls, contaminant and dirt repellency, Gtechniq Crystal Serum Ultra and Serum Light are the pinnacle in paint protection.

- Wheel Armour:

Why Use Gtechniq C5 Wheel Armour?

C5 Wheel Armour offers the best protection for wheels, repelling brake dust and contaminants and making them easier to maintain.

Because of C5’s unique, exceptionally fine surface rheology and chemical bonding mechanism, its performance is outstanding. The former property gives the coating its excellent stain and contaminant resistance, and the chemical bond formed between the wheel surface and C5 makes the coating durable.

C5 will retain its integrity up to temperatures of 600oC making it suitable for all parts of your vehicle’s rims and brake callipers.

15ml of C5 will cover the rim faces only of up to 17 inch wheels

30ml of C5 will cover the inside and out of any wheels up to 20 inch wheels

- Leather Guard:

Why Use Gtechniq Leather Guard?

L1 Leather Guard forms a durable abrasion resistant matte finish which offers the best ever protection against abrasion damage, UV rays, dye transfer and other discolouration.

With added BioCote® antimicrobial technology, treated surfaces will kill 99.9% of bacteria.

Friction protection is particularly important on seat bolsters, seat piping and any other high wear areas. The anti stain function is most relevant for light coloured leathers which are typically stained by dark coloured fabrics such as indigo jeans.

L1 gives 3 to 12 months durability depending on how high-wear the area protected is.

Myth buster

Many leather products market themselves on how they feed leather, when in fact this is not needed. Modern automotive leather uses synthetic fat liquors which do not evaporate. Any product that is designed to feed leathers will not be absorbed by modern automotive leathers but instead, remain on the surface attracting dirt which will then act as an abrasive foreshortening the leathers finish.

- Smart Glass

Why Use Gtechniq G1 ClearVision Smart Glass?

Unlike regular rain repellent coatings that adhere to the surface of the glass using relatively weak physical bonds, G1 uses a chemical bond which gives G1 unrivalled durability.

G1 ClearVision Smart Glass is extremely durable, the hydrophobic function improves wet weather visibility helping to improve safety and eye strain. It also makes removing contaminants from the glass such as ice, bugs and tree sap much easier.

G1 will only work on glass substrates and so, it will not work on modern headlight lenses which are made from polycarbonate. For these you will need to use G5 Water Repellent for Glass and Perspex.

Choose the 15ml bottle for windscreens only, but the 100ml bottle if looking to use on all of your car’s glass. G1 is supplied with G2 Residue Remover.